on Tuesday, May 5th, 2015

This article appeared in Auckland Today.

RPM International Tool and Die has been exporting tooling for more than 20 years and competes against, amongst others, product from China, the US, Italy and Portugal. As the main export market for New Zealand, Australia is also a major area of business for this Auckland based company.

“In addition to our local trade and reputation, of which we are very proud and committed, we have now entered markets in the US, China, Thailand and England and are now establishing a foot hold into the Chilean marketplace, after the New Zealand Government signed a free trade agreement with them 18 months ago.” Says Mark Vincent, RPM’s Director of Sales and Marketing. Exciting times for this company, who in only three decades have gone from humble beginnings to one of the country’s largest engineering operations.

The machinery, technology, tool design and production facilities are second to none and the highly skilled tool designers, operating from RPM’s purpose-built 30,000 sq. ft. premises on Auckland’s North Shore, create tools and dies to make everything from stadium seating through to dishwasher components.

RPM services both the local market and an extensive international client base, specialising in high end automation, press tools and injection moulded tooling for all engineering disciplines in the packaging, electronic, white ware, plastics and automotive industries, together with precision components for the medical and aviation sectors. RPM’s portfolio of projects spans over three decades and demonstrates clearly the innovative diversity achievable with aim and commitment to producing the highest quality tooling in the market.

The team at RPM strive to ensure that their customers are included in the design and manufacture of every project. Keeping them fully informed and involved every step of the way. Mark says “We’ve always treated our customers as number one. We don’t keep them at arm’s length.”

Example of tooling for thin wall container moulding.

Whilst there is local competition, tooling is a small industry within New Zealand with all the firms knowing of each other. The workload is shared amongst the groups to the customer’s benefit. However the size and manufacturing capabilities at RPM really set them apart in the industry, with manufacturing lead times being very short compared to the world market. This is a major and unique selling point for the company that lends itself both to local trade and export business. The recent change in the exchange rate makes New Zealand pricing more economical, which has made us even more competitive in the US and Chilean markets.”

Chile represents a strong market for New Zealand firms; and with most Chilean people and companies familiar with New Zealand because of the Carter Holt Harvey brands; a company that boldly expanded into Chile, establishing itself firmly in the forestry and plastics industries and, more recently, dairying. RPM’s Mark Vincent comments “Chilean’s are very familiar with our country, Chile is on the same latitude to New Zealand, with a similar climate and they’re very prepared to do business with us. When I travel overseas to visit companies, they really appreciate seeing the owners of a company coming through the door, not just a sales rep and that plays an important role in forming those strong relationships.”

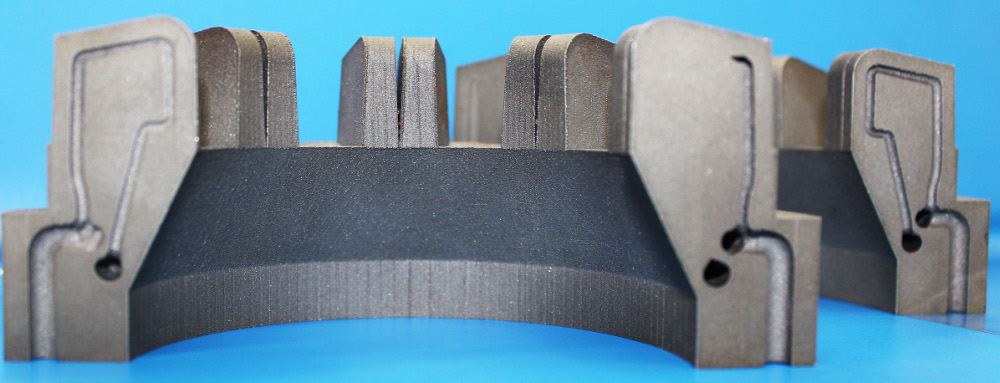

Laser sintered insert showing integrated internal cooling channels

RPM’s three directors, Mark, Peter Smith and Aaron Dwight are all hands on, working alongside a strong team of 40 engineers and support staff, including five full time tool designers. They describe their key challenge in the industry as being able to be cost effective and keeping their lead times short to maintain their competitive advantage. Mark says, “Every customer wants the job done yesterday.”

The competitive nature of the tooling industry results in high quality finished products, so RPM are keen to offer their best sell on what they can give their customers – their capabilities and experience – and for RPM that is the overall tool design. While many shops don’t have their own tool designers, RPM have five full time and that’s helps enormously with winning new projects.

The use of PTC Creo – an award winning 2D and 3D CAD software (formerly known as Pro Engineer), as a worldwide based system, Mark explains ensures RPM are operating world class facilities from right here in New Zealand.”

Also used at RPM is a new technology from the marketplace called Conformal Cooling, which is revolutionising aspects of tooling. This technology involves laser sintering inserts out of powdered metals, or more simply, the ability to grow an insert, layer by layer out of a metal powder, incorporating very intricate internal geometry to form cooling channelling that follow the flow of a cavity, hence the conformal cooling. This innovative procedure can produce shortened cycle times, improved plastic part quality, reduce warpage and—above all— result in cost reductions.”

It comes down to experience, expertise, commitment to quality, reinvestment and an outstanding team of highly qualified staff. “Our key business achievement is being at the forefront of the industry,” Mark says. “The testament is the many major customer relationships we have throughout the world who keep coming back to us time and time again.”

One such customer is packaging firm Cospak Pty Ltd, a customer of RPM International Tool and Die for the past 18 months. “They approached us because they knew our capabilities, the world class quality of our products, our speed to market and that we could provide them with strong tool maintenance programmes. They required high running and high speed tools that make millions of products.” RPM deliver on all counts.

Group Technical Advisor Cospak Australia and New Zealand, Steve Habershon confirms this. He knew of RPM for 25 years but had only used them occasionally as they were not perceived to be at the budget end of the tool-making fraternity that the company generally used.

“When our largest ever project emerged where we had invested a lot of IP we decided that the tooling had to be first class and we wanted to keep it in New Zealand and not have, for instance a Chinese toolmaker show our designs around, which are patented,” Steve says.

“We knew RPM were capable of producing what we needed but they exceeded expectations. They are a nice bunch of blokes and the company has a very professional air about it. Very good to work with at all levels, design, technical and management.”

Thank you to our suppliers who advertised alongside this article: