on Tuesday, August 4th, 2015

In days gone by, RPM have been strong advocates of using Copper Electrodes to spark fine detail in to cavities, however with the complexity of today’s designs and the tight tolerances required in each mould design, the copper electrodes were struggling to meet the increasing demands of a busy workshop.

Copper No More.

The cost for the ever growing quantity of copper electrodes required to finish a job was creeping higher. But more than that, the material was not keeping up with increasing demands.

As the copper electrodes heat up, the material begins to stress relieve and flex. This can result in the slightest, but most significant of moves in the electrode positioning. The knock on effect is that the tolerance of the sparked details is compromised. The shape of the electrode is diminished and the required result was often only just achieved as a result. This is particularly problematic when EDMing (sparking) extremely fine detail into tool steel. As the slightest flex in the electrode results in unacceptable results.

Additionally the limitations to the amount of detail that can be included on a copper electrode means more copper electrodes are required to achieve the designed finish. This, paired with the higher wear rate of copper electrodes and the slower processing times all lead RPM to want to try something different.

Graphite Electrodes Lead the Way

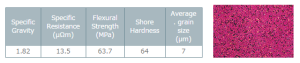

Now, RPM uses a HK series EDM graphite from Japan, The graphite is much lighter with a smaller coefficient of thermal expansion than Copper and therefore has less thermal distortion.

This is one of a large range of High Quality EDM graphite grades available. It is a precision finish grade that gives excellent EDM results and achieves a similar surface finish to the results gained from Copper Electrodes. There are denser grades available, but this one fits the bill for RPM.

The fine grain of the Graphite allows for a very similar surface finish to be achieved as from Copper, but with minimal electrode wear.

Graphite electrodes will wear at a very low rate in relation to the depth of cut, and will work with much more vigorous and aggressive machine parameters than Copper electrodes. It performs well at high current density, and is preserved through long processing times, compared to the Copper Electrodes that would wear far more quickly.

Designers can incorporate complex geometry and varying detail on a single graphite electrode and still maintain integrity to the design. This reduces number of electrodes required to complete a task significantly, saving on time and cost.

Graphite material is more economically priced than Copper. The reduced cost gives engineers a design freedom to produce electrodes that will give maximum effectiveness in their application, e.g. multiple electrodes with different spark gaps reducing overall sparking time.

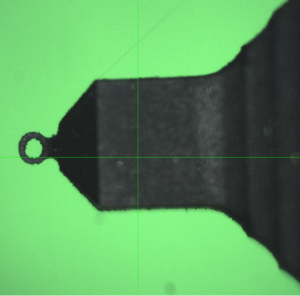

The cost of machining Graphite is lower than Copper. It is soft but dense, making it the perfect material to produce extremely fine detail. An example of which can be seen below.

This photo is an electrode, machined to demonstrate the fine intricacies possible when using Graphite. It looks like an extremely fine point has been machined at the tip.

However on closer inspection, under a highly magnified camera, we can actually see that a round, with an OD of 0.5mm, and an ID of 0.3mm has been machined into to the head of the ele ctrode. The hole is barely visible to the naked eye, but has been machined with a 0.1 mm wall section, demonstrating the extent of detail that can be achieved from Graphite.

ctrode. The hole is barely visible to the naked eye, but has been machined with a 0.1 mm wall section, demonstrating the extent of detail that can be achieved from Graphite.

The example above would not be functional as an electrode, as the fine detail would crumble under the electrical current required to generate the detail. However it demonstrates the potential of what can be achieved.

Graphite electrodes remove metal in the EDM process quickly and easily in comparison to the high temperatures and run times of equivalent copper electrodes. When considered in conjunction with all other benefits; cost, stability, machining ease, fine detailed results, finish and process time, it is clear to RPM that Graphite electrodes are the most effective and efficient way to work.

At RPM, we have a dedicated CHMER HE65 3 Axis Machine that is used solely for the manufacture of Graphite Electrodes.

Chmer HE-65

Graphite CNC Machining Centre

Travel – 500 x 600 x 350mm

Spindle Speed – 30,000 rpm

Multiple Electrode Positions

We run a specific brand of cutters designed to machine graphite electrodes to the finest detail and have a recycle system in place to ensure that every block of graphite is used to produce as many electrodes as possible.

To demonstrate our confidence in machining Graphite Electrodes for use in EDMing, RPM are able to offer customised, quality measured graphite electrodes, including CAD/CAM engineering as required at an attractive price. Our experience and expertise can guide you through best practices and operating procedures and will guarantee to offer cost savings as a major benefit to using Graphite Electrodes along with reduced processing times and optimising your competitive edge.

Graphite electrodes showing recycling symbol, food grade plastic symbol and Rib detail.

The number of electrodes that can be machined simultaneously is only limited by the space in the machine. Each electrode position can be programmed individually for position and machining.

This photo demonstrates the graphite loaded into the holders before machining.

This photo demonstrates the same graphite, after machining is complete. The graphite blocks have been shaped into fine detail for EDMing (sparking) the shape into steel.

For more information on customised, quality measured graphite electrodes, including CAD/CAM engineering, please feel free to contact our sales department for a no obligation quote. 09 479 8844.